At public charging stations for electric vehicles, the trend is clear: equipment is evolving into multifunction systems where interaction occurs via outdoor touchscreens acting as human–machine interfaces (HMI).

These solutions transform how drivers engage with the infrastructure, elevate the user experience, improve operations and contribute to hardware longevity.

“A good HMI can make the difference between an excellent, poor or even non-existent user experience,” recognises Marco González Masillo, Head of Sales for Iberia at Data Modul, during the “Data Modul Day” organised by Mobility Portal.

The premise is simple: if the interface does not work, neither does the charger.

For manufacturers and charge point operators (CPOs), the HMI is not just an information module; it is the charger’s “face”.

“It forms part of the product image and the manufacturer’s corporate identity,” González Masillo explains.

That first impression directly affects user trust and perceived service quality.

The display can also become an additional asset. Integrated as a digital signage platform, it enables richer user information, event broadcasting and on-site marketing and communications campaigns.

“This makes the HMI more than a mere information or service element,” the Data Modul representative underlines.

Outdoor HMI: sunlight readability, thermal management, and protection against impacts and moisture

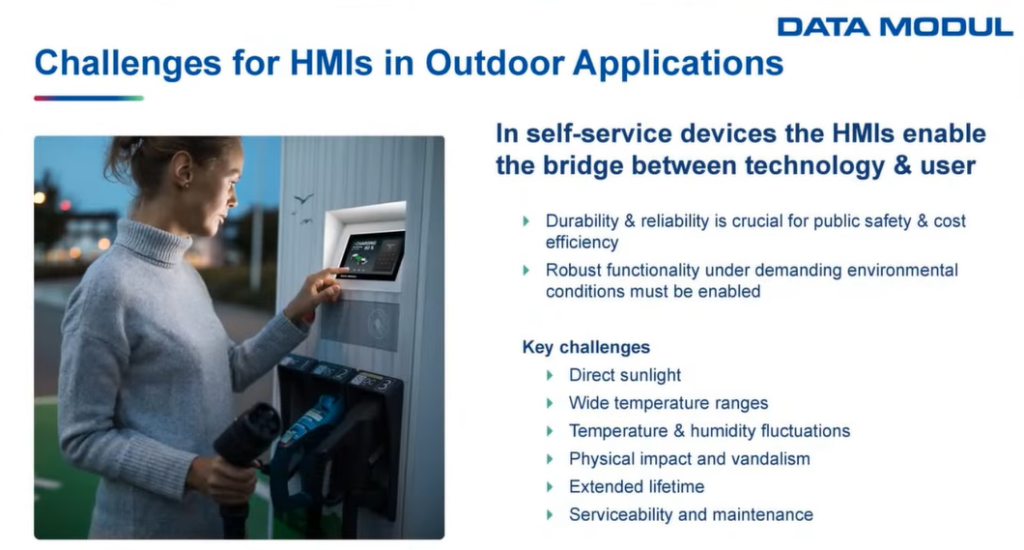

In self-service devices, when the equipment fails the bridge between user and technology breaks. Therefore, durability and reliability are critical in public spaces.

On this point, Diana Nanu, Head of Product and Markets – Mobility at Data Modul, notes:

“Our advice when designing HMI solutions for outdoor applications is to address these challenges from the earliest stages to ensure the final device is robust, intuitive and able to operate under extreme environmental conditions, whether intense sunlight, temperature fluctuations, humidity, or even physical impacts and vandalism.”

All these factors must be managed so that the integrated system delivers service over a long period.

“It is important to understand that there is a trade-off between selecting the right components to enable functionality and the robust integration needed to withstand all the factors mentioned,” Nanu adds.

Outdoors, the screen must be readable in full daylight and is exposed to solar radiation—an unfavourable environment.

“An HMI that cannot be read in sunlight is of no use; a touch surface that does not respond outdoors is equally unusable,” the executive acknowledges.

For this reason, high-brightness displays with strong contrast and good colour reproduction are used, viewable from any angle and able to deliver the experience defined by the manufacturer.

It is worth mentioning that functionality largely depends on integration.

The screen is never “naked”: it is mounted in a housing, usually behind a protective glass, and that construction must not compromise legibility.

“At Data Modul we always recommend optical bonding to avoid reflection losses between the display and the glass. The surface treatment of the glass should also be chosen to improve legibility and the user experience,” Nanu comments.

And what does this have to do with visibility in full sun?

“It is all about reflection losses and the physics behind them. In addition, sunlight includes IR and UV radiation, which negatively affects the electronic components of the screen and the system’s thermal management,” she explains.

Schematics show that filling the gap between display and cover glass reduces reflections and improves thermal dissipation.

The choice of adhesive or additional filters can further protect the display from solar radiation and increase its service life. UV and IR radiation are also linked to temperature issues: outdoors, ranges are extreme.

High temperatures can cause panel discolouration or blackening and damage adhesives or bonds; low temperatures can reduce touch responsiveness.

“For this reason, selecting displays, electronics and components with an extended temperature range is critical for outdoor HMIs,” the executive underlines.

“Our touch solutions include optical and structural bonding methods implemented in-house. From the earliest design phases we analyse the relevant issues to ensure integration and technical monitoring, making sure the system operates correctly,” she adds.

Data Modul also addresses humidity and water ingress in outdoor devices, aiming to meet IP65 certification or higher.

“Depending on the type of integration, we adapt open-frame or pre-assembled solutions, combining structural adhesives and seals to achieve the required protection,” Nanu continues.

Impact resistance is another essential point: the glass must withstand blows and the frame construction should provide shock absorption.

“An optically bonded screen can withstand an impact at its centre, but if the glass is larger than the display and lacks absorption, this creates problems when certifying charging stations,” she warns.

She concludes: “Our goal is for HMI units to be robust and provide reliable 24/7 operation. Thanks to our expertise in sensors and controllers, we can optimise system functionality and monitor its operation over the long term.”

The extensive technical requirements for HMI solutions for EV chargers demonstrate how closely product quality, durability, and energy efficiency are linked. In addition, customers and the market have increasingly high expectations for resource-efficient products. Our sustainability approach supports this demand by placing greater emphasis on durable components. This allows us to create a solid foundation for combining technical excellence with more sustainable solutions step by step.

About Data Modul

With over 50 years’ experience in industrial display solutions, Data Modul provides electronic solutions for sectors that demand robustness, durability and reliability, including manufacturing, automotive, healthcare and transport.

The company focuses on the latest technologies and stands out for its customisation capability, tailoring each solution to the customer and the end device.

For electric-vehicle (EV) chargers, Data Modul addresses market needs with two core building blocks: displays and embedded computing.

It supplies displays in a wide range of sizes and technologies and also delivers complete HMIs engineered to maximise user experience and withstand the conditions of public-realm installation.In embedded computing, it offers standard or bespoke solutions in two main architectures: single-board computers (SBCs) and systems-on-module (SoMs) integrated into a carrier board designed either by the customer or by Data Modul.

Discover Mobility Portal Data

Discover Mobility Portal Data, a new, exclusive market-intelligence platform offering reliable datasets and essential reports to support informed decision-making across the automotive sector—from combustion and electric vehicles to charging infrastructure.

Research, trend analysis and well-organised statistics, presented with clarity and precision, together with up-to-date insights—all just one click away. With Mobility Portal Data, better decisions are within reach.

READ MORE

-

Connectivity, DC and high power: ORBIS’ three technology bets for eMobility charging in 2026

ORBIS is heading into 2026 with a clear technological focus: stronger connectivity, further development of its DC solutions and a decisive push towards high-power charging. The Spanish manufacturer is fine-tuning its portfolio to align with the evolving European regulatory framework, while introducing its new Viaris ISI charger.

-

The charger’s ‘face’: why the HMI decides the success—or failure—of public chargers

Touchscreens at charge points act as the human–machine interface (HMI). If the interface fails, so does the charger. How can we ensure an optimal customer experience?

-

EV panorama in Europe: electric cars pass the 20% mark as BYD steps up its EU push

Europe’s electric vehicle market continues to gain ground: battery-electric cars exceed a 20% monthly share in November, BYD triples its registrations, and Tesla extends its loss of momentum, according to the latest data from ACEA.