The European electric vehicle (EV) battery market faces significant challenges in its expansion, making local production investment a strategic priority.

According to a report by Meticulous Research, the battery market is expected to surpass 415.9 billion dollars in the coming years, with a compound annual growth rate (CAGR) of 33.1% until 2031.

This increase is largely driven by governmental policies aimed at reducing battery prices and increasing investment in manufacturing.

However, technological and geopolitical uncertainties also play a crucial role in shaping investors’ decisions.

One of the primary challenges is Europe’s reliance on international supply chains for raw materials such as lithium, a critical element for the lithium-ion batteries dominating the market.

Tensions between global powers like China and the United States, alongside rapid technological advancements in the Asian nation, have raised concerns about the stability of supply chains.

In this context, experts emphasise the importance of investing in local battery production, but which destinations within Europe are most attractive for these projects?

Michel Bayings, Senior Management Consultant at Emobility Consulting France/Netherlands, highlights that political stability and clear long-term objectives are key factors in attracting investment to the continent:

“Investments are directly linked to stable political environments with clear objectives.”

“This is something that is currently lacking in many EU countries, where, after elections, the future direction becomes uncertain,” he tells Mobility Portal Europe.

In his view, Germany remains one of the strongest destinations, but complex factors such as energy policies must be considered.

In the Netherlands, battery investments are harder to make profitable due to policies allowing for compensation for photovoltaic solar energy fed back into the grid.

In contrast, Germany has managed to attract more investment thanks to its more favourable energy cost environment.

David Santiago, CEO of TERA Batteries Recycling, underscores the strategic importance of certain countries within Europe’s automotive sector.

“Spain has been a benchmark in car manufacturing for years. Looking at the numbers, it’s the second-largest vehicle producer in the EU and has risen to eighth globally,” he notes.

He adds: “This is a clear sign that the country is not only capable of manufacturing but also of leading in the electric mobility value chain.”

Proximity to vehicle manufacturers, coupled with investments in infrastructure, positions the Spanish-speaking nation as a key location for cells production, especially for players seeking a dynamic market with an established supply chain.

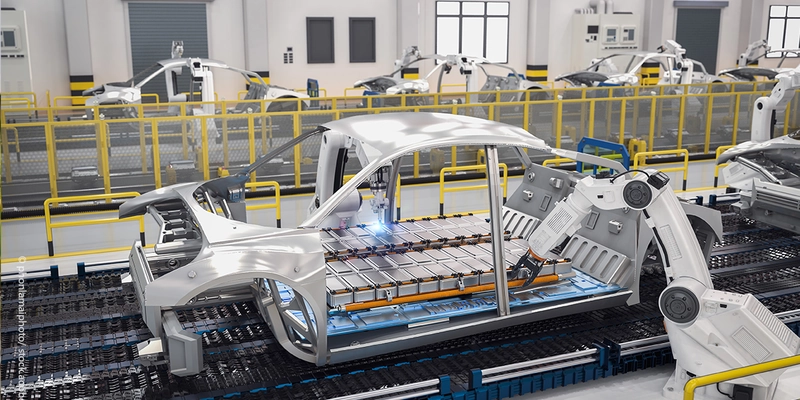

EV adoption drives the need for local battery production

However, challenges remain.

The scarcity of lithium, high production costs, and the rapid pace of technological advancement make it difficult for large battery manufacturing projects to remain profitable in the long term.

Industry experts warn that battery technology is advancing faster than internal combustion vehicles, creating uncertainty around the viability of certain investments.

“Technological advances may render plants obsolete before they even begin operating. This is a risk that investors must consider,” they argue.

A case in point is Automotive Cells Company (ACC), a joint venture between Stellantis, Mercedes-Benz, and TotalEnergies.

ACC had planned to build three gigafactories in Europe by 2026 but recently halted construction of its German plant while reassessing its business model.

Rising costs and a slowdown in EV sales have led to this reassessment, a trend not unique to ACC, as other companies are taking similar approaches to align their projects with market realities.

During this consolidation phase, choosing the right technology that remains competitive in the long term is crucial.

Meanwhile, Eastern European countries such as Hungary and Poland have emerged as key players in battery production, partly due to their lower land and labour costs.

Read more: Poland: why is it the new European epicenter of battery factories?

These nations have attracted investments from major Asian manufacturers like CATL and LG Chem, which have set up factories to meet Europe’s growing demand.

Proximity to vehicle production hubs in Germany and the ability to offer lower operational costs have made these countries appealing to investors.