General Motors (GM) and its battery partner LG Energy Solution announced plans to begin commercial production of new, low-cost lithium manganese-rich (LMR) battery cells in the United States in 2028.

The new cells are expected to be cheaper than current nickel-rich chemistries, while still enabling extended range for future electric trucks and full-size SUVs.

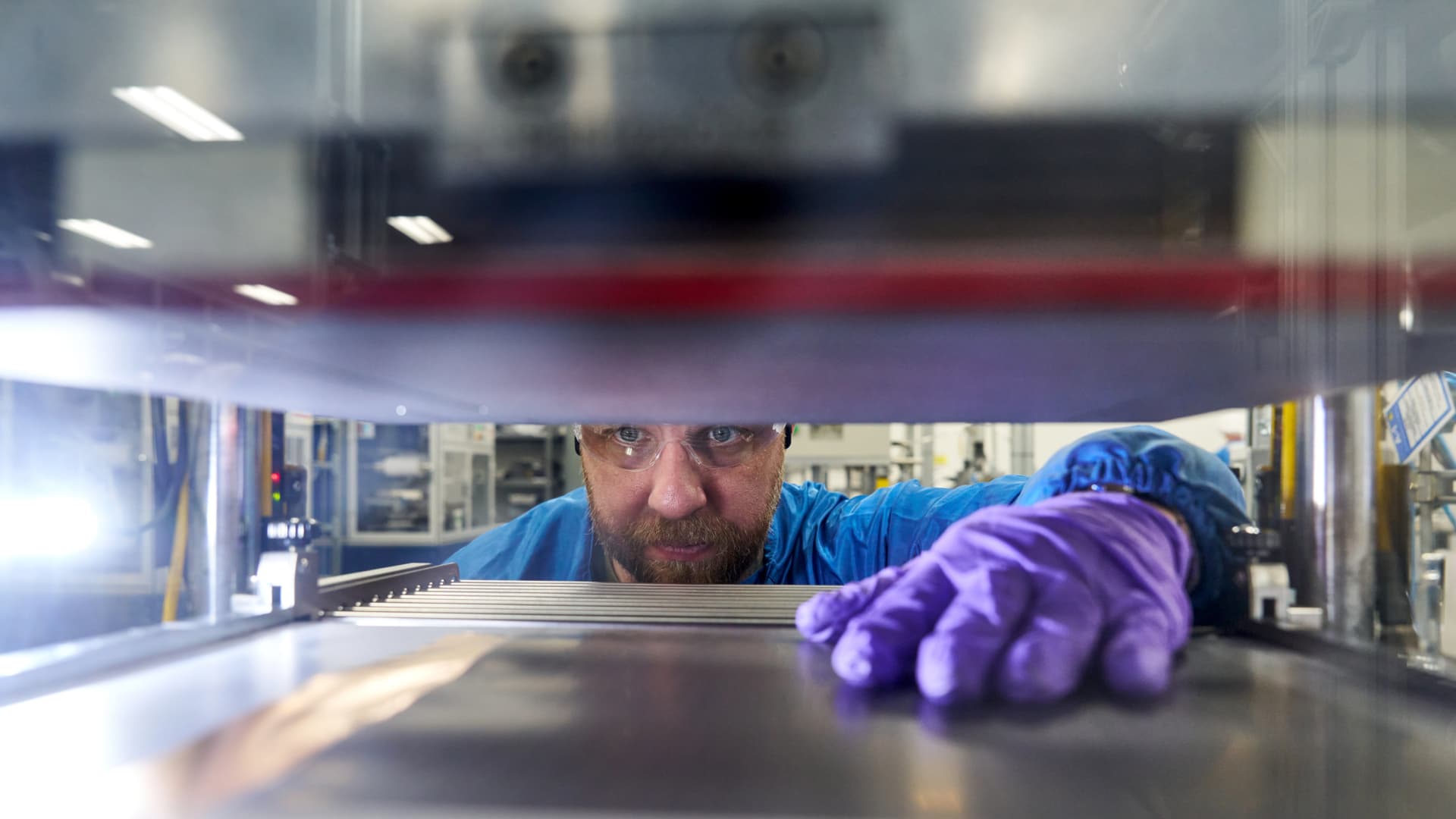

In addition to the new chemistry, the LMR cells will adopt a prismatic format, replacing the current pouch-type design.

According to GM, this change will reduce the number of components in battery packs by over 50%, simplifying manufacturing and lowering production costs.

The initiative is part of GM’s broader strategy to achieve cost parity between electric and internal combustion vehicles, through the integration of flexible battery chemistries that balance range, performance, and affordability.

“We’re adopting flexible chemistries for the best balance of range, performance and affordability,” said Kurt Kelty, GM’s Vice President of Battery, Propulsion and Sustainability. “My mission here is to get as many EVs on the road as possible. We need to get price parity with ICE vehicles—then this thing’s just going to take off.”

Production to Take Place at Ultium Cells Plants

The LMR cells will be produced at one of the two Ultium Cells joint-venture facilities operated by GM and LG in Ohio and Tennessee.

With these prismatic LMR cells, GM expects to offer more than 400 miles (over 640 kilometers) of range on a single charge in electric trucks, while also significantly reducing battery costs, Kelty said.

The automaker is targeting a reduction of $30 per kilowatt-hour in battery pack costs by 2025, although it has not disclosed its current cost per kWh.

Expanding Battery Chemistry Portfolio

In parallel, GM also plans to introduce vehicles using lithium iron phosphate (LFP) battery cells, which are generally less expensive than nickel-based cells. Further details about this initiative will be shared soon, according to Kelty.

GM aims to be the first automaker to commercially deploy LMR cells in its EVs. However, Ford Motor is also exploring this technology, as noted in a recent blog post by its Director of Electrified Propulsion Engineering.

This development reflects the auto industry’s growing focus on cost-effective battery innovations to support the scaling of electric mobility.

By reducing battery prices while maintaining long-range capabilities, manufacturers like GM seek to make EVs more accessible to mass-market consumers and increase adoption rates.