By 2025, the Italian startup Novac plans to launch an energy storage system based on “super-capacitors” to the market.

“We are raising funds, seeking investors to join the current ones to establish a production line, in order to supply prototypes to different stakeholders,” explains Matteo Bertocchi, CEO of the company, in dialogue with Mobility Portal Europe.

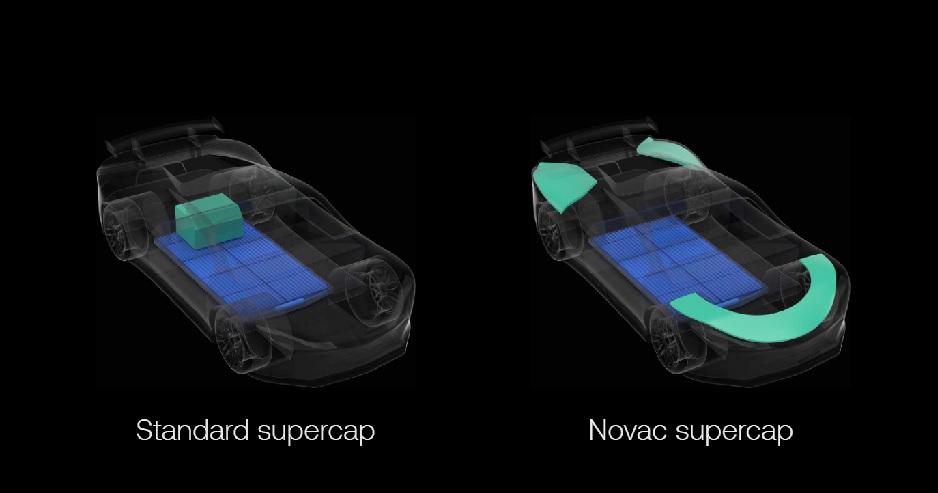

And he continues: “Our goal is to place super-capacitors in the structure of vehicles and other electrical applications, integrating them into carbon fibers to avoid the need for additional packages or boxes that take up space.”

Through the solid-state, safe, and moldable “Supercap,” the company helps electric vehicle (EV) manufacturers surpass their competitors in efficiency and performance.

The truth is that this technology brings several advantages to the automotive market.

Firstly, it facilitates passing safety tests due to the absence of liquid electrolytes.

Additionally, vehicle integration is much simpler since it does not require designers to find the necessary space, as the Novac supercap replaces pre-existing parts thanks to its moldability.

Moreover, thanks to the high power density, charging times can be drastically reduced.

This technology can be adapted to any type of vehicle and is also complementary to other systems such as batteries and fuel cells.

It is worth mentioning that the supernova is not limited to application in electric vehicles.

On the contrary, this technology can be applied in e-bikes, scooters, drones, electric boats, and even spacecraft.

“We want to reach various markets, including automotive, smart mobility, drones, and space, where there is a need for a lot of power in limited spaces,” acknowledges Bertocchi.

Other characteristics of Novac’s super-capacitors

One of Novac’s super-capacitor differentiators is its solid-state nature, as the absence of liquid avoids the risk of leaks, explosions, and evaporation.

Furthermore, this system is moldable, making it possible to adapt it to different surfaces and volumes, thereby reducing overall dimensions and facilitating design.

In terms of its anatomy, it consists of a surface composed of several layers, two electrodes separated by an electrolyte, all components developed by the Novac team.

This “trilayer” is covered with a protective carbon fiber case for structural purposes.

Italian eMobility sector requests incentives

When asked about the obstacles facing the electromobility sector, Bertocchi highlights two.

One of them concerns “the shortage of charging stations.”

“This leads to range anxiety among users, making it difficult to adopt electric vehicles,” he adds.

The second obstacle concerns “the cost of electric vehicles.”

It is worth noting that the EV market share in the country is only four per cent, below the regional average of around 14 per cent.

“There could be more help from the government, especially considering that companies like Stellantis will start building factories in Italy in the coming years,” indicates the CEO.

It is worth recalling that in recent days the exchange between Carlos Tavares, CEO of Stellantis, and Italian authorities has been a topic of discussion.

The truth is that Prime Minister Giorgia Meloni demanded that the multinational industrial group increase the production of electric vehicles in the national territory.

In response, Tavares said: “Italy should do more to protect jobs in the automotive sector instead of looking for scapegoats and attacking Stellantis NV, the owner of Fiat.”

The businessman stated that if subsidies for the purchase of electric vehicles are not granted, Italian plants are at risk.